Vinit Stainless, a well-known producer and supplier in Chennai, India, is renowned for providing premium stainless steel 321H bars made for applications requiring high temperatures and pressures. The high-carbon equivalent of 321 that provides improved creep resistance and mechanical strength at higher temperatures is SS 321H. For accuracy, longevity, and adherence to international standards, Vinit Stainless uses high-quality raw materials and contemporary manufacturing processes to create its 321H bars. Reliable and corrosion-resistant stainless steel bars that are suited to the requirements of demanding industrial environments are what we provide to a variety of industries, including the power generation, oil and gas, heat treatment, and chemical processing sectors.

In order to improve strength and creep resistance, stainless steel 321H bars have a higher carbon content (0.04–0.10%) than regular 321 and contain 17–19% chromium and 9–12% nickel. In order to stabilise the alloy and stop carbide precipitation during welding, titanium is added in an amount that is at least five times the carbon content. SS 321H has a yield strength of roughly 205 MPa and a tensile strength of 515–750 MPa. At temperatures as high as 900°C, it retains outstanding mechanical qualities and oxidation resistance while providing good weldability and structural integrity under heat stress.

| Standard | ASTM A276 / A479, ASME SA276 / A479 |

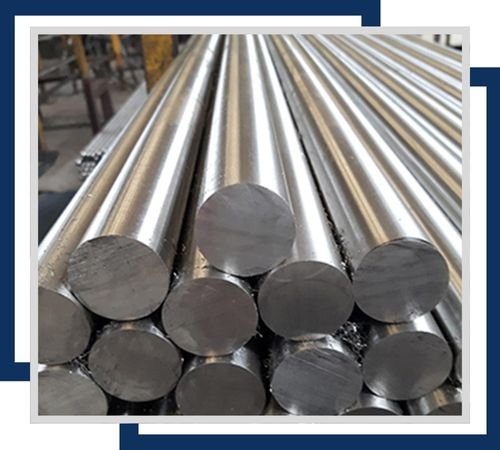

| Round Bar Size | 3mm~ 800mm |

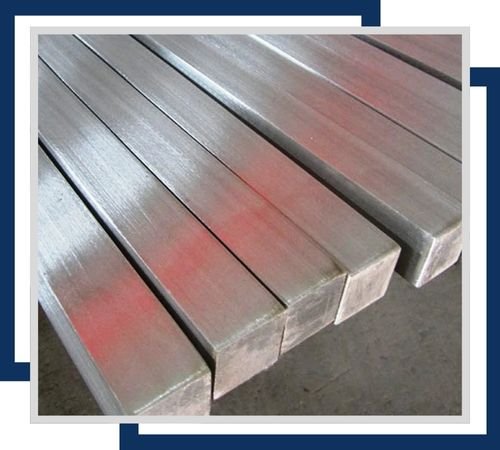

| Square Bar Size | 4mm* 4mm ~100mm* 100mm |

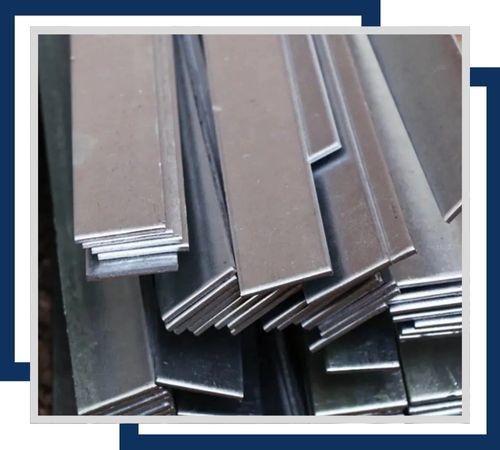

| Flat Bar Size | 2mm ~ 100mm |

| Hex Bar Size | 2mm ~ 100mm |

| Angle Size | 3mm* 20mm* 20mm~ 12mm* 100mm* 100mm |

| Thickness | 50 mm to 6000 mm Long |

| Length | 1 To 6 Meters, Custom Cut Length |

| Form | Round, Square, Hex(A/F), Rectangle, Billet, Ingot, Forging Etc |

| Grade | C | Mn | Si | P | S | Cr | N | Ni | Ti | SS 321H | 0.04 – 0.10 | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 – 19.00 | 0.10 max | 9.00 – 12.00 | 4(C+N) – 0.70 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1457 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Contact us to get a quick quote for your requirement.

Stainless Steel 321H Round Bars are designed for high-temperature applications, offering excellent oxidation resistance and mechanical strength. Ideal for use in aerospace, chemical processing, and high-temperature industrial components where durability and resistance to thermal degradation are crucial.

Stainless Steel 321H Flat Bars provide superior strength and resistance to high temperatures and oxidation. Suitable for manufacturing structural components, heat exchangers, and exhaust systems, these bars are used in industries where high performance under extreme conditions is required.

Stainless Steel 321H Square Bars are engineered for high-stress, high-temperature environments. They are commonly used in aerospace, petrochemical, and power generation industries for components such as reactor vessels, furnace parts, and structural supports due to their excellent thermal stability and strength.

Stainless Steel 321H Rectangular Bars offer high resistance to thermal and oxidation damage, making them suitable for high-temperature applications like furnace components, chemical processing equipment, and structural supports in demanding environments.

Stainless Steel 321H Hexagonal Bars provide exceptional strength and thermal stability, ideal for use in high-temperature applications such as gas turbines, exhaust systems, and chemical processing equipment. Their resistance to carbide precipitation ensures durability under extreme conditions.

Stainless Steel 321H T-Bars are utilized in high-temperature and high-stress environments, offering excellent strength and resistance to oxidation. They are commonly used in structural applications, including supports and frames in the aerospace, chemical processing, and energy sectors.

Applications requiring high-temperature strength and resistance to intergranular corrosion frequently use stainless steel 321H bars. Oil and gas, power generation, chemical processing, and thermal processing equipment are examples of common industries. Boilers, pressure vessels, heat exchangers, superheaters, and furnace components that are subjected to high mechanical and thermal stress are perfect candidates for these bars. Because of its enhanced creep resistance, SS 321H is especially well-suited for extended use in hot environments. Because it provides stability and durability in harsh conditions, it is also favoured in welded structures where post-weld heat treatment is impractical.

©2024 Vinit Stainless All Rights Reserved.