Vinit Stainless is a prominent manufacturer and supplier of SS 347H bars in Chennai, India, providing high-strength stainless steel bars designed for high-temperature applications. SS 347H is a stabilized austenitic stainless steel with columbium (niobium) added to it for greater resistance to intergranular corrosion and improved creep strength. The “H“ grade suggests increased carbon content, enhancing strength at high temperatures. In Vinit Stainless, our SS 347H bars are renowned for their high strength, weldability, and thermal resistance. The bars find extensive applications in the power generation, refinery, and aerospace sectors in challenging structural uses.

17–20% chromium, 9–13% nickel, 0.04–0.10% carbon, stabilized by columbium. It offers tensile strength of 585 MPa, yield strength of 240 MPa, and elongation of 35%. Higher carbon content increases high-temperature creep resistance, and columbium stabilizes the structure to avoid carbide precipitation. It has superior oxidation resistance up to 870°C and good performance during intermittent service up to 925°C. SS 347H has good mechanical strength under cyclic heating and cooling conditions and can be welded using common fusion and resistance methods.

| Specifications | ASTM A276 / ASME SA276 |

| Dimensions | ASTM, ASME |

| Range | 3.17 MM TO 350 MM DIA |

| Diameter | 25mm to 152mm |

| Length | 1 to 6 Meters, Custom Cut Length |

| Finish | Bright, Polish & Black |

| Form | Round, Square, Hex (A/F), Rectangle, Wire (Coil Form), Wiremesh, Billet, Ingot, Forging |

| Condition | Cold Drawn & Polished Cold Drawn, Centreless Ground & Polished |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 347H | min. | 0.04 | – | – | – | – | 17.0 | 3.00 | 9.0 | – |

| max. | 0.10 | 2.0 | 1.00 | 0.045 | 0.030 | 19.0 | 4.00 | 13.0 | – | |

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 347H | 515 | 205 | 40 | 92 | 201 |

Contact us to get a quick quote for your requirement.

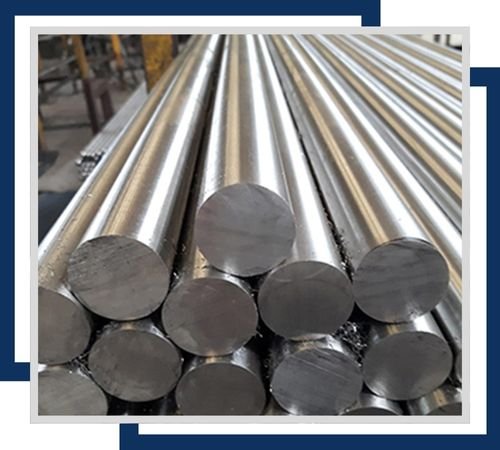

Stainless Steel 347H Round Bars offer excellent corrosion resistance. Available in sizes ranging from 3mm to 200mm in diameter, these bars are ideal for applications in high-temperature environments due to their stability and durability.

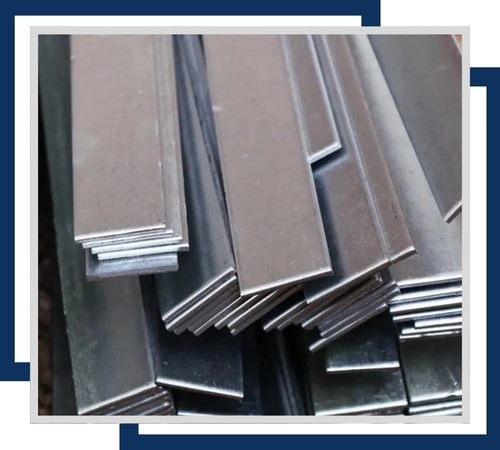

These bars provide outstanding resistance to corrosion and oxidation. Stainless Steel 347H Flat Bars come in thicknesses from 1mm to 50mm and widths from 10mm to 500mm, making them suitable for a variety of industrial uses.

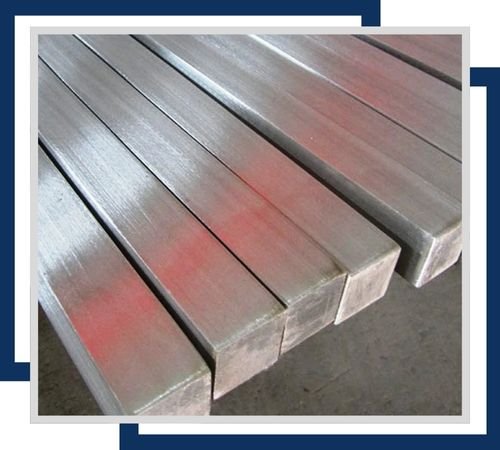

Stainless Steel 347H Square Bars are perfect for high-stress applications. Available in sizes from 5mm to 100mm, they combine excellent mechanical properties with superior resistance to intergranular corrosion.

These bars are highly resistant to corrosion and scaling. Stainless Steel 347H Rectangular Bars are available in thicknesses from 1mm to 50mm and widths from 10mm to 500mm, ideal for structural and mechanical applications.

Stainless Steel 347H Hexagonal Bars offer excellent resistance to high temperatures and corrosion. Available in sizes ranging from 6mm to 75mm, they are widely used in the manufacturing of fasteners and other high-strength components.

These corrosion-resistant bars are available in a range of sizes. Stainless Steel 347H T-Bars provide excellent mechanical strength and are ideal for structural applications requiring high resistance to oxidation and corrosion.

SS 347H bars are extensively applied in applications requiring long-term high-temperature exposure, like boilers, pressure vessels, superheaters, and heat exchangers. The alloy can also be applied to piping systems, catalytic reactors, furnace equipment, and thermal shields. In petrochemical and chemical sectors, SS 347H bars are used in transfer piping, flue gas ducts, and refinery systems. The bars provide assurance in adverse operating conditions where thermal fatigue resistance, corrosion resistance, and stress rupture resistance are essential. They possess excellent weldability and dimensional stability, making them well-suited for parts that need long service life in aggressive thermal environments.

©2024 Vinit Stainless All Rights Reserved.