Vinit Stainless is a top supplier and maker of SS 348H bars in Chennai, India, supplying high-temperature stainless steel items for significant industrial purposes. SS 348H is a high-carbon niobium-stabilized austenitic stainless steel with better creep resistance at elevated temperatures. At Vinit Stainless, our SS 348H bars are produced under vigorous quality control to provide better stability, very good oxidation resistance, and longer service life. Our SS 348H bars find applications in high-temperature and pressure processes in the chemical, refinery, and thermal power industries. We supply SS 348H bars in various specifications and finishes.

SS 348H contains 17–20% chromium, 9–13% nickel, ≤0.10% carbon, and niobium (columbium) for stabilization. It possesses a tensile strength of 585 MPa, yield strength of 240 MPa, and elongation of 35%. The alloy is resistant to intergranular corrosion, retains its structural integrity following long-term thermal exposure, and endures high-pressure operations. It provides good weldability and formability, retaining its mechanical characteristics up to 870°C. The niobium content of SS 348H inhibits carbide precipitation and thus is recommended for high-temperature welded equipment and thermal cycle usage.

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 348H | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 17 – 19 | – | 9 – 13 | – |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Contact us to get a quick quote for your requirement.

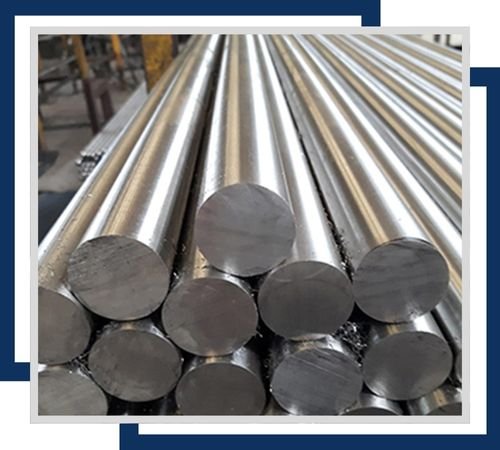

348H round bars offer high-temperature strength and corrosion resistance, ideal for aerospace, chemical processing, and nuclear applications requiring durability and reliable performance under extreme conditions.

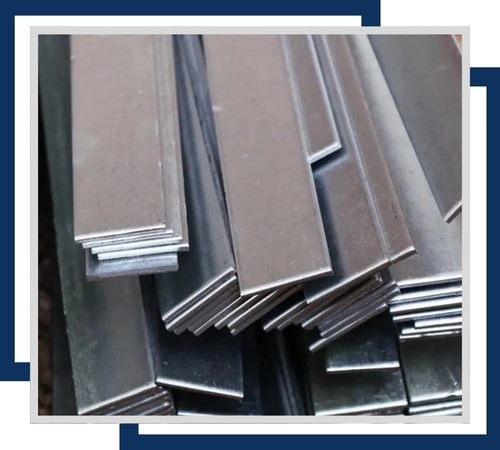

348H flat bars provide excellent resistance to oxidation and intergranular corrosion, suitable for heat exchangers, boiler tubes, and furnace components in high-temperature industrial environments.

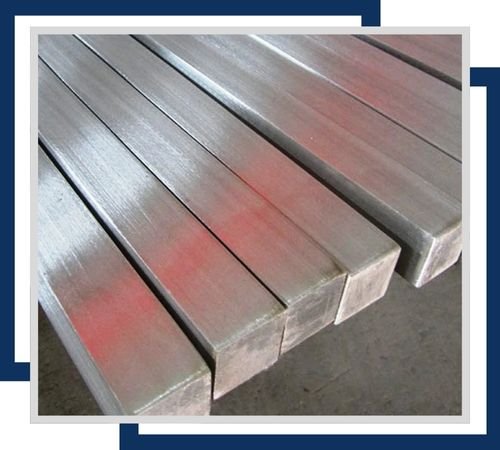

348H square bars are used in high-stress applications, offering superior strength and stability for structural components in aerospace, chemical, and nuclear industries.

348H rectangular bars deliver robust performance in high-temperature environments, ideal for critical components in chemical processing equipment, heat exchangers, and nuclear reactors.

348H hexagonal bars provide excellent mechanical properties and corrosion resistance, perfect for fasteners, fittings, and other components in demanding aerospace and industrial applications.

348H T-bars offer high strength and corrosion resistance, suitable for structural support in high-temperature environments such as chemical plants and power generation facilities.

SS 348H bars are applied to heat exchangers, superheaters, boiler tubes, and reactor vessels of power and chemical plants. The alloy is applicable in high-temperature services where thermal stability and resistance to corrosion are required. It‘s widely used in petroleum refineries, aircraft engine parts, exhaust manifolds, and furnace components. SS 348H is especially useful for welded assemblies subject to high heat and pressure. It works well under conditions involving acidic or chloride-bearing solutions. The bars are also applied in petrochemical equipment and steam piping systems that need resistance against stress corrosion cracking and thermal fatigue.

©2024 Vinit Stainless All Rights Reserved.