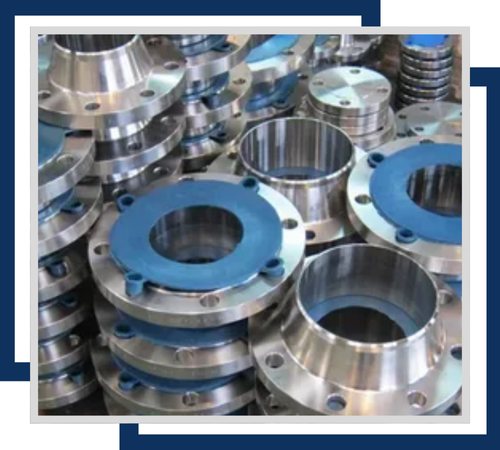

Based in Chennai, India, Vinit Stainless has made a name for itself as a top producer and supplier of premium stainless steel goods. Vinit Stainless, renowned for its superiority in producing long-lasting and corrosion-resistant materials, provides a wide selection of Stainless Steel 348H Flanges. These flanges are designed to function exceptionally well in corrosive and hot conditions. They are made with premium-grade SS 348H alloy enhanced with titanium, which guarantees exceptional strength, stability, and oxidation resistance. Our flanges, which are made for use in vital piping systems, meet the exacting requirements of industries all over the world with unparalleled dependability and efficiency.

With titanium added to stabilize the structure against intergranular corrosion, Stainless Steel 348H is a high-carbon austenitic stainless steel alloy that contains roughly 18–20% Chromium, 8–10% Nickel, and 0.8–1.2% Carbon. These flanges have outstanding mechanical durability, creep resistance, and high-temperature strength. Tensile strength of approximately 515 MPa, yield strength of 205 MPa, and elongation of 40% are typical mechanical characteristics. The alloy is perfect for use in demanding industrial settings because it resists oxidation, sulfuric acid, and nitric acid while maintaining its structural integrity under heat stress.

| Standard | ASTM A182 / ASME SA182 |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges |

| Size | 1/2″ (15 NB) to 48″ (1200NB) |

| Class/Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| SS 348H | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 – 19.00 | 0.10 max | 9.00 – 12.00 | 5(C+N) – 0.70 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1457 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Contact us to get a quick quote for your requirement.

SS 348H slip-on flanges offer excellent resistance to high temperatures and corrosion, making them ideal for demanding industrial applications. They are easy to install and provide strong, reliable connections in piping systems.

SS 348H weld neck flanges provide exceptional strength and resistance to high temperatures and corrosion. They are ideal for critical applications, offering robust and leak-proof connections in demanding environments.

SS 348H Lap Joint Flange offers excellent resistance to oxidation and corrosion, ensuring durability in high-temperature environments. Ideal for piping systems, it ensures easy assembly and disassembly for maintenance.

SS 348H blind flanges are designed to seal the end of pipes, providing a strong, corrosion-resistant barrier in high-temperature applications. They ensure system integrity and are ideal for maintenance and pressure containment.

SS 348H ring-type joint flanges offer superior sealing in high-pressure and high-temperature applications. Their precision-engineered design ensures leak-proof connections, making them ideal for demanding environments in industries like petrochemical and aerospace.

SS 348H forged flanges provide exceptional strength and durability, ideal for high-temperature and corrosive environments. Their forged construction ensures high structural integrity and reliability in critical industrial applications and piping systems.

We carry out robust quality tests on stainless steel 348H flanges to provide superior performance and reliability. The products undergo extensive inspection in-house. We facilitate third-party to facilitate when they are needed. Our focus is always on timely delivery to ensure our clients receive their orders without compromising quality or performance.

Industries that are subjected to high temperatures and corrosive conditions frequently use stainless steel 348H flanges. Chemical processing units, power generation facilities, petrochemical plants, and aerospace systems are examples of common applications. Heat exchangers, reactor vessels, steam and gas turbines, and high-temperature piping systems are among the parts that these flanges are perfect for. They are particularly well-suited for critical processing systems and marine environments due to their exceptional resistance to oxidation, sulfuric and nitric acids, and mechanical fatigue. They are a popular option for demanding industrial operations because of their strength and weldability, which guarantee long-term dependability and ease of installation.

©2024 Vinit Stainless All Rights Reserved.