One of the top producers and suppliers of stainless steel 415 bars is Vinit Stainless, a reputable brand in the stainless steel sector with headquarters in Chennai, India. Our SS 415 bars are manufactured with premium-grade raw materials and contemporary manufacturing techniques, and are designed for applications that demand exceptional strength, toughness, and moderate corrosion resistance. These bars are well-known for their superior mechanical performance and hardenability, making them perfect for heat-treated structural applications. In India and internationally, Vinit Stainless is dedicated to providing dependable, superior products that satisfy international standards to a wide range of industries, including heavy machinery, aerospace, automotive, and defence.

High-strength martensitic stainless steel alloys, such as stainless steel 415 bars, are usually made up of 0.05–0.15% carbon, 11.5–13.5% chromium, and trace amounts of nickel, manganese, and molybdenum. Improved corrosion resistance, toughness, and hardness are all benefits of this composition. Following appropriate heat treatment, SS 415 bars can reach yield strength of about 450 MPa and tensile strength of 620–850 MPa. The material can reach hardness levels of 35 to 40 HRC and retains good wear resistance. 415 bars work well in mechanical environments with high stress and mild corrosion, but they are not as resistant to corrosion as austenitic grades.

| Specifications : | ASTM A240 / ASME SA240 |

| Dimensions : | ASTM, ASME and API |

| Standard : | JIS, AISI, ASTM, GB, DIN, EN, etc. |

| Surface : | 2B, 2D, BA, NO.4, NO.8, 8K, Mirror,Checkered, Embossed, Hair Line, Sand Blast, Brush, Etching |

| Width : | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm,etc. |

| Finish : | Black,Bright Polished,Rough Turned,No.4 Finish,Matt Finish,BA Finish |

| Length : | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc. |

| Grade | C | Mn | P | S | Si | Ch | Ni | Mo |

| SS 415 | 0.05 max | 0.50-1.00 | 0.030 max | 0.030 max | 0.60 max | 11.5-14.0 | 3.5-5.5 | 0.50-1.00 |

| Tensile Strength R₃ N/mm² | 700-800 | 700-800 | 700-800 | 700-800 | 700-800 | 700-800 | 700-800 |

| 0.2% Offset Yield Strength Rᵖ ≥N/mm² | 520 | 520 | 520 | 520 | 520 | 520 | 520 |

| Elongation in 2 inches, % | 15 min | 15 min | 15 min | 15 min | 15 min | 15 min | 15 min |

| Grade | Density lbm/in3 | Melting Range(°F) | Thermal Conductivity(BTU-in/hr- ft. °F) | Electrical Resistivity(in x 10-6) | Modulus of Elasticity (psi x 106 | Coefficient of Thermal Expansion (in/in)/°F x 10-6 | Specific Heat(BTU/lb/°F) |

|---|---|---|---|---|---|---|---|

| 415 | -at 68°F: 0.280 | 2700 to 2790 | 187 at 212°F | 23.7 at 68°F | 29 | 6.0 at 32 – 212°F | 0.11 at 68°F to 212°F |

| – | – | – | – | – | 7.5 at 68 – 1200°F | – |

Contact us to get a quick quote for your requirement.

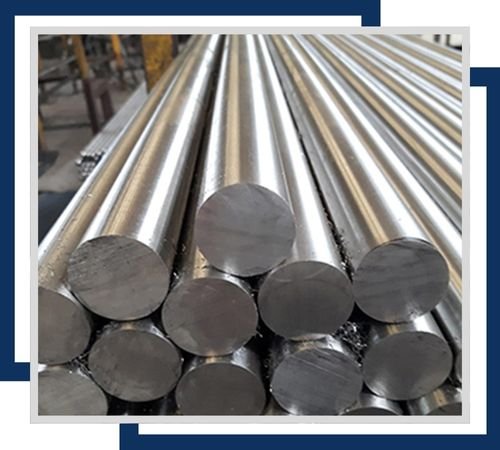

SS 415 (Precipitation Hardening) Bar Round Bar is a high-strength stainless steel alloy, known for its excellent corrosion resistance, toughness, and hardness. It is commonly used in applications requiring high strength-to-weight ratios, such as aerospace, automotive, and structural components. It undergoes a heat treatment process for enhanced properties.

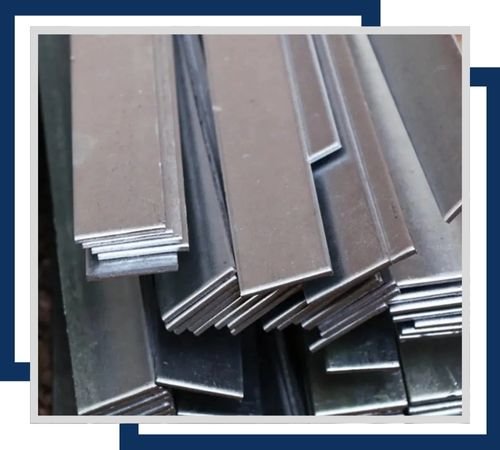

Stainless Steel 415 Flat Bar is a precipitation-hardening alloy known for its excellent strength, corrosion resistance, and hardness. It is widely used in industries such as aerospace, defense, and automotive, offering high strength-to-weight ratios. The flat bar undergoes heat treatment for improved mechanical properties and durability.

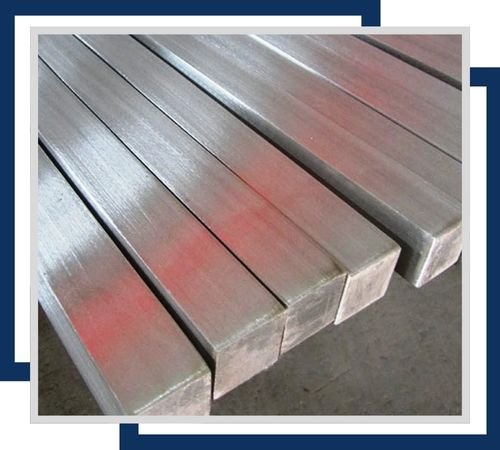

SS 415 Bar Square Bar is a precipitation-hardening stainless steel offering high strength, corrosion resistance, and hardness. It is commonly used in industries such as aerospace, defense, and automotive for applications requiring strong, durable materials. The square bar is heat-treated to enhance its mechanical properties and performance.

Stainless Steel 415 Rectangular Bar is a precipitation-hardening stainless steel known for its exceptional strength, corrosion resistance, and hardness. Commonly used in aerospace, automotive, and defense industries, this bar offers high mechanical properties and durability. It is heat-treated for enhanced strength and wear resistance in demanding applications.

SS 415 Bar Hexagonal Bar is a high-strength, corrosion-resistant stainless steel alloy. It undergoes precipitation hardening to enhance its hardness and mechanical properties. Typically used in aerospace, automotive, and defense industries, this hexagonal bar provides excellent durability, wear resistance, and strength for demanding structural and mechanical applications.

SS 415 Bar T-Bar is a precipitation-hardening stainless steel known for its high strength, excellent corrosion resistance, and hardness. Often used in aerospace, automotive, and industrial applications, this T-shaped bar provides enhanced mechanical properties after heat treatment, offering durability and reliability in demanding structural and mechanical components.

Many demanding applications that call for a blend of strength, toughness, and moderate corrosion resistance use stainless steel 415 bars. These bars are perfect for applications involving mechanical stress and wear in automotive parts, shafts, fasteners, pump parts, gears, and aerospace components. They are also used in construction tools, oil and gas machinery, and defence equipment where structural integrity is essential. Precision components subjected to dynamic loading and thermal cycles can benefit from the hardenability and durability of SS 415 bars. They are a dependable material choice in the engineering and manufacturing sectors due to their strength and machinability.

©2024 Vinit Stainless All Rights Reserved.