Stainless Steel 422 Tubing is an 11–13% chromium-containing high-strength martensitic stainless steel alloy with 0.20–0.25% carbon, 0.90–1.30% molybdenum, and small quantities of nickel, manganese, and silicon. The alloy is made to resist high temperatures and provides superior creep resistance. Its tensile strength is 895–1100 MPa, yield strength is 620–790 MPa, and hardness is up to 260 HB. The tubing also resists deterioration under high-stress conditions and withstands scaling up to 1200°F (650°C), which makes it suitable for heat-treated and stress-loaded uses.

| Specifications | ASTM A/ASME SA268/A731 CL |

| Dimensions | ASTM, ASME and API |

| SS 409 Pipes | 1/2″ NB – 24″ NB |

| ERW 409 Pipes | 1/2″ NB – 24″ NB |

| EFW 409 Pipes | 6″ NB – 100″ NB |

| Wall Thickness | Schedule 5S – Schedule XXS |

| Schedule | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Type | Seamless / ERW / Welded / Fabricated / LSAW Pipes |

| Form | Round Pipes, Custom Pipes, Square Pipes, Rectangular Pipe, “U” Shape, Hydraulic Pipes |

| Length | Single Random, Double Random & Cut Length. |

| End | Plain End, Beveled End, Treaded |

| Grade | 409 | |

|---|---|---|

| min | max | |

| C | – | 0.03 |

| Mn | – | 1.00 |

| Si | – | 1.00 |

| P | – | 0.04 |

| S | – | 0.02 |

| Cr | 10.5 | 11.7 |

| Mo | – | – |

| Ni | – | 0.5 |

| N | – | – |

Contact us to get a quick quote for your requirement.

Stainless Steel 422 Seamless Tubing is available in sizes ranging from 0.5 to 8 inches in diameter. It offers excellent resistance to corrosion and high temperature oxidation. Ideal for applications requiring smooth internal surfaces and high mechanical properties.

Stainless Steel 422 Welded Tubing comes in dimensions up to 12 inches in diameter. It provides robust corrosion resistance and is typically used in applications where high strength and durability are required. Suitable for fluid transport and structural applications.

Stainless Steel 422 Heat Exchanger Tube is available in various sizes, typically ranging from 0.5 to 2 inches in diameter. It boasts excellent resistance to corrosion and high thermal conductivity. Used in systems requiring efficient heat transfer under corrosive conditions.

Stainless Steel 422 Instrumentation Tubing comes in sizes from 0.125 to 1 inch in diameter. It offers high corrosion resistance and precision, making it perfect for critical measurements and control systems. Ensures reliability and durability in instrumentation applications.

Stainless Steel 422 Boiler Tubes are available in sizes up to 4 inches in diameter. They are highly resistant to corrosion and oxidation at high temperatures. Essential for efficient operation and longevity in boiler systems.

Stainless Steel 422 U-Tubes are custom-sized according to specific requirements, generally ranging from 0.5 to 2 inches in diameter. They offer exceptional corrosion resistance and are designed for efficient heat transfer in compact spaces. Ideal for heat exchangers and condensers.

Stainless Steel 422 Condenser Tube is available in sizes ranging from 0.5 to 2 inches in diameter. It provides excellent resistance to corrosion and high thermal conductivity, ensuring efficient condensation processes. Widely used in power plants and refrigeration systems.

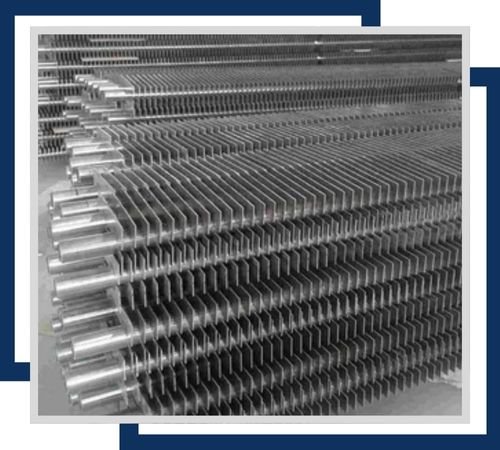

Stainless Steel 422 Fin Tubes come in various sizes, typically from 0.5 to 2 inches in diameter, with custom fin heights and spacing. They offer superior corrosion resistance and enhanced heat transfer efficiency. Ideal for heat exchangers in demanding environments.

Vinit Stainless is a leading supplier, and stockist of high-quality stainless steel 422 tubing in Chennai, India. Our products are widely used in various applications, and we are committed to delivering excellent service, resulting in high customer satisfaction. Our unique finishing techniques further distinguish us in the stainless steel industry. We are dedicated to consistently providing superior products and effectively meeting our customer’s needs.

Stainless Steel 422 Tubing is designed for high-temperature, high-stress applications like aerospace, turbine, and power generation. It finds wide application in parts such as turbine blades, aircraft exhaust components, and fasteners that function under extreme conditions. Its high creep strength and oxidation resistance qualify it for application in steam turbines, heat exchangers, and nuclear reactor components. The tubing is also utilized in petrochemical plants and industrial furnaces where high-temperature performance is essential. Its resistance to high temperature and structural stability under thermal cycling also make it most valuable in crucial mechanical and energy-oriented installations.

©2024 Vinit Stainless All Rights Reserved.