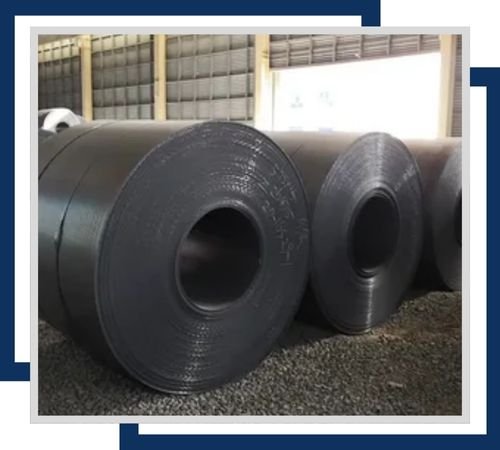

Based in Chennai, India, Vinit Stainless is a reputable and skilled manufacturer and supplier that specializes in providing high-performance stainless steel products. The Stainless Steel 446 Coils stand out among its extensive selection due to their exceptional quality and dependability. These coils have outstanding resistance to corrosion, oxidation, and high temperatures because they are designed to function in harsh conditions. Vinit Stainless is dedicated to quality and makes sure that every product satisfies strict industry requirements. We are a preferred partner in the stainless steel industry because we concentrate on providing value through long-lasting materials, prompt service, and total customer satisfaction.

High-chromium ferritic stainless steels, such as stainless steel 446 coils, are mainly made up of 23–27% chromium, a low carbon content, and trace amounts of silicon, manganese, and molybdenum. Because of their composition, they are more resistant to corrosion and scaling in high-temperature settings. Their mechanical properties, which guarantee structural integrity and durability, include a tensile strength of roughly 485 MPa, a yield strength of 275 MPa, and an elongation of 20%. They are perfect for demanding applications where corrosion and heat resistance are crucial due to their exceptional thermal stability and resistance to chemical attack.

| Standard | ASTM A240, ASME SA240 |

| Thickness | 0.1mm to 12 mm Thk |

| Coil Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm etc. |

| Coil Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm etc. |

| Surface | 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sandblast, Brush, etching. |

| Finish | Hot rolled (HR), Cold rolled (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated), Galvanized etc. |

| Grade | C | Ni strong> | Si | S | Mn | P | Cr | Ti | |

| SS 446 | Min | – | – | – | – | – | – | 10.5 | 6x C |

| MAX | 0.08 | 0.5 | 1.00 | 0.045 | 1.00 | 0.045 | 11.75 | 0.75 | |

| Tensile Strength(MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Rockwell B (HRB) max | Brinell (HB) max |

| 450 | 240 | 25 | 75 | 131 |

Contact us to get a quick quote for your requirement.

SS 446 Slitting Coils are processed by slitting larger coils into narrower strips. They offer excellent resistance to high-temperature oxidation and thermal fatigue. These coils are ideal for use in applications involving high heat and severe environments.

SS 446 Hot Rolled Coils are produced through high-temperature rolling, making them suitable for heavy-duty applications. They possess high resistance to oxidation, particularly in environments where high heat is a concern. These coils are commonly used in industrial equipment and furnaces.

SS 446 Cold Rolled Coils are cold-formed to achieve a smoother finish and higher strength. These coils are ideal for precision applications, offering improved surface quality and tight tolerance. They maintain excellent resistance to heat and corrosion.

Stainless Steel 446 HR Slitting Coils are hot-rolled and then slit into narrow widths for further processing. They offer superior oxidation resistance and high strength at elevated temperatures. These coils are widely used in industries like aerospace and power generation.

Stainless Steel 446 Slitting Coils are designed for applications requiring high-temperature strength and corrosion resistance. These coils are slit into precise widths and are ideal for high-stress environments. They maintain their mechanical properties even at extreme temperatures.

AISI 446 Slitting Coils are manufactured from high-alloy stainless steel, offering excellent resistance to thermal fatigue and oxidation. They are commonly used in applications such as furnaces, kilns, and combustion chambers. The slitting process ensures flexibility for different industrial needs.

We are committed to delivering the highest quality Stainless Steel 446 Coils to our clients. For their excellent quality, these coils undergo a series of stringent testing processes before dispatch. These tests include hardness testing, chemical analysis through spectro analysis, positive material identification (PMI) testing, flattening testing, micro and macro tests, pitting resistance testing, flaring testing, and intergranular corrosion (IGC) testing. Besides that, we also provide third-party inspection certificates for the assurance of our clients in respect of the excellent quality and reliability of our Stainless Steel 446 Coils for a wide variety of industrial applications.

446 Stainless Steel Industries that need materials that can withstand high temperatures and corrosive conditions frequently use coils. These coils are perfect for boiler parts, heat exchangers, and industrial furnaces. They are commonly used in chemical processing industries that deal with harsh acids and chemicals, and they are also appropriate for thermal processing equipment. They are widely utilized in power plants and automobile exhaust systems because of their resistance to oxidation and scaling. They are a great option for marine applications because of their resistance to seawater corrosion, which guarantees enduring performance in saltwater conditions.

©2024 Vinit Stainless All Rights Reserved.