SS 904L has 19–23% chromium, 23–28% nickel, 4–5% molybdenum, 1–2% copper, and ≤0.02% carbon. The combination gives great resistance to depleting acids like sulfuric acid and chloride-induced corrosion. It gives a tensile strength of 490–710 MPa, yield strength of 220 MPa (min), and elongation of 35%. SS 904L retains strength under high temperature and severe corrosive conditions. It is non-magnetic and weldable and resists intergranular corrosion even in the as-welded condition, and hence it is best suited for chemical processing.

| Standards | ASTM / ASME |

| Designation | B 649, SB 649 |

| Grade | 904L Round Bars and Rods 904L Round Bars and Rods: ASTM B 649, ASME SB 649 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Cu |

|---|---|---|---|---|---|---|---|---|---|

| SS 904L | 0.020 max | 2 max | 1 max | 0.040 max | 0.030 max | 19.0-23.0 | 4.0-5.0 max | 23.00 – 28.00 | 1.0-2.0 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 7.95 g/cm3 | 1350 °C (2460 °F) | Psi – 71000 , MPa – 490 | Psi – 32000 , MPa – 220 | 35% |

Contact us to get a quick quote for your requirement.

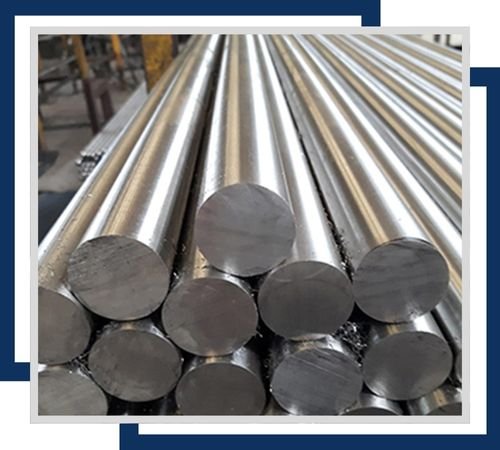

904L round bars offer high resistance to corrosion and oxidation, ideal for harsh environments in chemical processing, marine, and pharmaceutical industries, providing durability and strength.

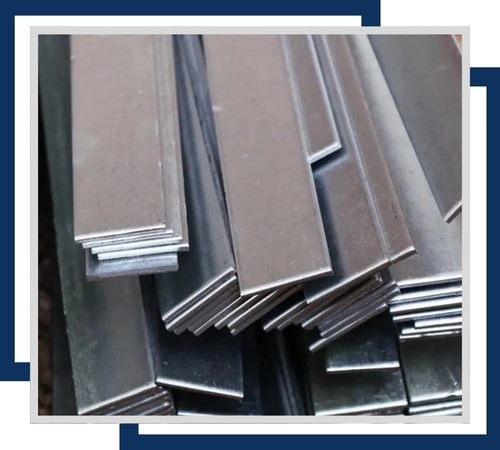

904L flat bars provide exceptional resistance to pitting and crevice corrosion, suitable for use in aggressive environments like chemical processing and marine applications, ensuring robust performance and longevity.

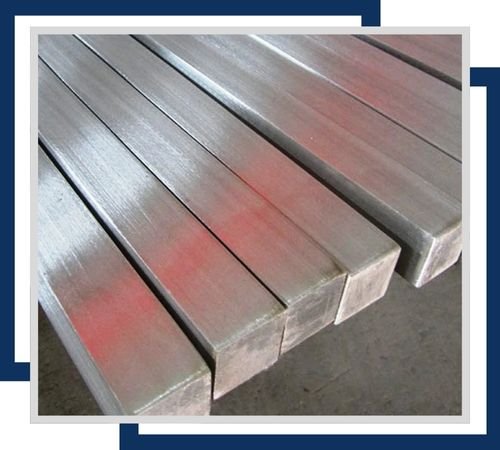

904L square bars deliver superior corrosion resistance and strength, perfect for structural applications in corrosive environments, such as chemical plants and marine environments, offering durability and reliability.

904L rectangular bars are designed for high corrosion resistance and strength, used in chemical processing, marine, and industrial applications, where durability and performance under harsh conditions are required.

904L hexagonal bars provide excellent corrosion resistance and are used in structural and mechanical applications, particularly in aggressive environments such as chemical processing and marine settings.

904L T-bars offer superior resistance to corrosion and high strength, ideal for structural support in corrosive environments like chemical plants and marine applications, ensuring long-lasting performance and reliability.

Vinit Stainless is a leading supplier, and stockist of high-quality stainless steel 904L bars in Chennai, India. Our products are widely used in various applications, and we are committed to delivering excellent service, resulting in high customer satisfaction. Our unique finishing techniques further distinguish us in the stainless steel industry. We are dedicated to consistently providing superior products and effectively meeting our customer’s needs.

SS 904L bars have extensive usage in industries dealing with aggressive reducing acids, such as sulfuric, phosphoric, and acetic acids. Typical applications are for heat exchangers, tanks, chemical reactors, pickling facilities, and marine parts. The bars also find application in drug processing, gas scrubbers, and pulp & paper applications. SS 904L is ideal for highly saline environments like seawater applications because of its good resistance to crevice and pitting corrosion. Its high toughness and strength make it suitable for shafts, valves, fasteners, and pressure vessels requiring corrosion and durability in severe, acidic, or chloride-dominated conditions.

©2024 Vinit Stainless All Rights Reserved.