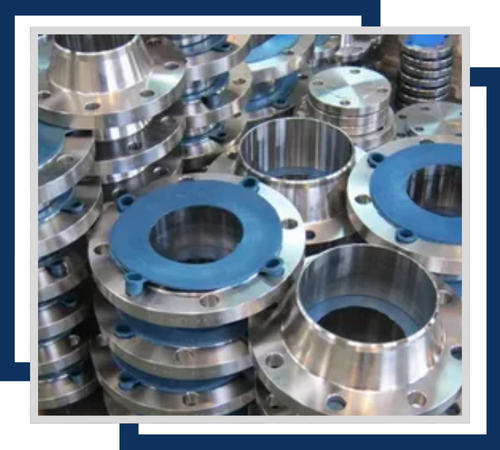

One of the top producers and suppliers of high-end stainless steel products, Vinit Stainless is situated in Chennai, India, and is well-known for its excellence, performance, and inventiveness. Stainless Steel 904L Flanges are among its best-selling products; they are designed to provide remarkable mechanical strength and resistance to corrosion in demanding industrial settings. These flanges, which come in a variety of designs like slip-on, blind, and weld neck, meet strict international standards. They guarantee exceptional performance in extremely corrosive media, such as sulfuric acid and chloride-rich environments, because they are made from non-stabilized austenitic stainless steel 904L, which has high concentrations of nickel and chromium.

Stainless Steel 904L is a non-stabilized, austenitic stainless steel alloy that contains trace amounts of copper and titanium along with 19–23% chromium, 23–28% nickel, and 4–5% molybdenum. Excellent corrosion resistance is offered by this composition, particularly in environments that contain acid and chloride. The flanges have exceptional mechanical qualities, such as high elongation and ductility, yield strength of about 220 MPa, and tensile strength of up to 710 MPa. Because their structure holds up well in high-temperature and high-pressure environments, they can be used in oxidizing and reducing settings and provide dependable, maintenance-free performance even in the most demanding applications.

| Standard | ASTM A182 / ASME SA182 |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges |

| Size | 1/2″ (15 NB) to 48″ (1200NB) |

| Class/Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Cu |

| SS 904L | 0.020 max | 2 max | 1.00 max | 0.040 max | 0.030 max | 19.00 – 23.00 | 4.00 – 5.00 max | 23.00 – 28.00 | 1.00 – |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.95 g/cm3 | 1350 °C (2460 °F) | Psi – 71000 , MPa – 490 | Psi – 32000 , MPa – 220 | 35 % |

Contact us to get a quick quote for your requirement.

SS 904L Slip On Flanges offer excellent corrosion resistance, high strength, and durability for industrial applications, ensuring reliable performance.

SS 904L ring type joint flanges are robust, high-corrosion-resistant components designed for high-pressure applications. They ensure a tight seal with their precision-machined grooves, ideal for extreme environments and demanding conditions.

SS 904L forged flanges are premium stainless steel fittings known for their superior strength and corrosion resistance. Ideal for high-pressure and harsh environments, they ensure reliability and durability in critical applications.

SS 904L long weld neck flanges are engineered for high-strength applications requiring extended weld connections. They offer exceptional corrosion resistance and structural integrity, making them suitable for demanding industrial environments.

SS 904L lap joint flanges are designed for flexibility and ease of assembly, featuring excellent corrosion resistance and strength. Their superior durability makes them ideal for applications in aggressive environments and high-pressure systems.

SS 904L Blind Flanges provide strong corrosion resistance, high durability, and are ideal for sealing pipe ends in demanding environments.

Each and every unit of Stainless Steel 904L Flange is well packed with high-grade substances to curb rust and damage in shipping. We hire an efficient means of transportation to ensure timely delivery to the customers since their satisfaction is top priority. Delivery happens to the clients with all necessary documentation such as certificates of compliance along with material specifications, to ensure transparency and trust.

Chemical processing, petrochemical, marine, and pharmaceutical industries are among the many that use stainless steel 904L flanges because they require resistance to corrosion, pitting, and crevice attack. They are crucial in refineries, offshore platforms, and desalination plants because they are perfect for handling solutions of sulfuric acid, phosphoric acid, and chloride. They are also appropriate for use in oil and gas and aerospace applications due to their exceptional strength, ductility, and heat resistance. For crucial operations in corrosive environments, SS 904L flanges provide unparalleled durability and dependability, whether in heat exchangers, pressure vessels, or piping systems.

©2024 Vinit Stainless All Rights Reserved.