Home > Sheet and Plates > Stainless Steel 904L Sheet and Plates

High-alloy austenitic stainless steel 904L has trace amounts of copper and titanium along with 19–23% chromium, 23–28% nickel, and 4-5 molybdenum. This composition is ideal for demanding service conditions because it offers exceptional corrosion resistance, particularly in environments that are acidic and chloride-rich. It exhibits remarkable hardness, high strength, outstanding weldability, and resistance to pitting and crevice corrosion. For crucial applications where performance and durability are crucial, its stability over a broad temperature range and resistance to oxidation, stress corrosion, and cracking make it the perfect choice.

The main benefit of stainless steel 904L is its exceptional resistance to harsh corrosive substances, especially seawater, sulfuric acid, and chlorides. It has excellent mechanical qualities, such as good formability, durability, and high tensile strength. It is a material of choice in industries that demand long-term dependability and low maintenance because of its capacity to preserve structural integrity under extreme heat stress and aggressive chemical exposure. It is a premium option for high-performance settings because of its non-magnetic nature, weldability, and low carbon content, which improve resistance to intergranular corrosion.

| Standard | ASTM A240, ASME SA240 |

| Thickness | 0.1mm to 12 mm Thk |

| Sheet and Plate Size | 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm |

| Surface | 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sandblast, Brush, etching. |

| Finish | Hot rolled (HR), Cold rolled (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated). |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Cu |

| SS 904L | 0.020 max | 2 max | 1 max | 0.040 max | 0.030 max | 19 – 23 | 4 – 5 | 23 – 28 | 1 – 2 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.95 g/cm3 | 1350 °C (2460 °F) | Psi – 71000 , MPa – 490 | Psi – 32000 , MPa – 220 | 35 % |

Contact us to get a quick quote for your requirement.

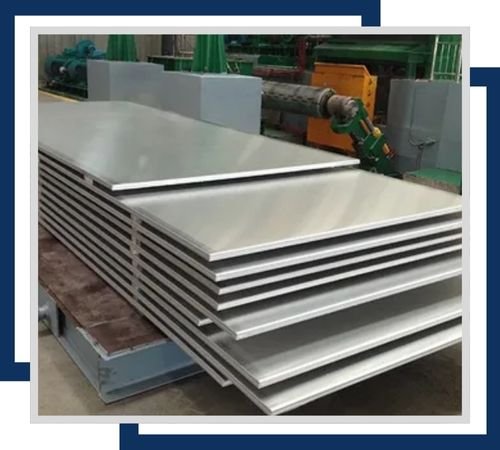

Stainless Steel 904L hot rolled sheets exhibit excellent corrosion resistance in aggressive conditions, such as acids and chlorides. Thicknesses range between 3mm to 25mm, while widths can be up to 2 meters in size. This sheet is employed in heavy-duty applications where robust structural integrity is demanded.

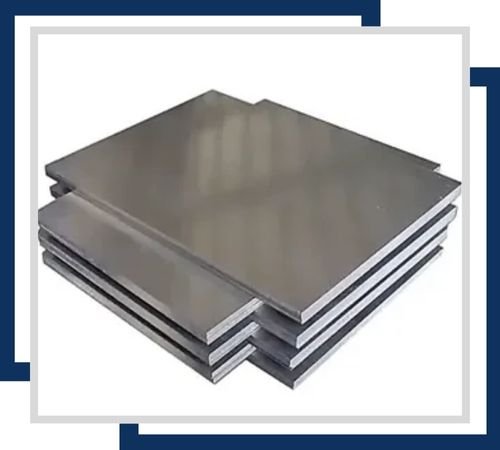

Stainless Steel 904L Cold Rolled Plates are alloyed with austenitic with excellent corrosion protection against strong acids and chlorides. These 904L sheets are available up to 0.5-3 mm, with widths ranging up to 1.5 meters. Plates are also featured with a highly smooth surface polish that can use for precise aesthetics.

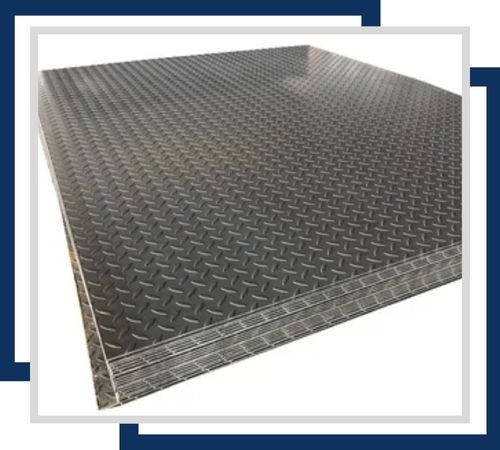

Stainless Steel 904L Chequered Sheets have a patterned surface that enhances slip resistance while maintaining excellent corrosion resistance. Available in common thicknesses of 2 mm to 6 mm and up to 1.2 meters in width, these sheets are ideal for flooring and other high-traction surfaces.

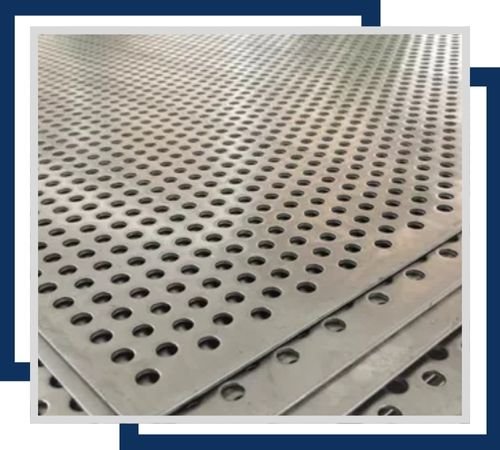

Stainless steel perforated plates from the 904L grade combine corrosion resistance with customized perforation patterns for ventilation and filtration. Thicknesses range from 1 mm to 8 mm, and the size up to 1.2 meters by 2.4 meters accommodates industrial and architectural applications.

Stainless Steel 904L Shim Sheets are excellent resistance to aggressive environments and precise thicknesses for the application. Normally available in a thickness range from 0.1 mm up to 3 mm and size up to 1 meter by 2 meters, these sheets are used for gap filling and alignment.

Stainless Steel 904L Polished Plates are known for their excellent finish and high corrosion resistance. They are very suitable for decorative and high-end applications. Thicknesses available are from 1 mm to 50 mm, and the maximum dimensions can go up to 2 meters by 6 meters, making them aesthetically pleasing and durable.

Vinit Stainless is committed to providing an experience of excellence to all its customers who purchase our Premium Quality Stainless Steel 904L Sheets and Plates by providing complete documents. We send the commercial invoice, packing list, fumigation certificate, heat treatment chart, quality assurance plan, and NABL-approved lab test report, which certifies the originality and high quality of our products. To further boost the confidence of our clients, we provide the Stainless Steel 904L Sheets and Plates with a range of test certificates, such as MTC as per EN 10204/3.1b, PMI Test Certificate, 100% radiography test report, and Third Party Inspection Certificate. We express our promising commitment to our customers in terms of satisfaction, and on going to evolve into excellence in product quality.

Applications requiring high mechanical strength and resistance to corrosion frequently use stainless steel 904L sheets and plates. Chemical processing is one typical industry that uses it in tanks, piping systems, and reactors that handle strong acids. Because of its exceptional seawater resistance, it is perfect for offshore oil platforms, shipbuilding, and desalination plants in maritime environments. It is also utilized in power generation apparatus, pressure vessels, and heat exchangers. Because of its longevity under harsh service conditions, corrosion resistance, and hygienic qualities, 904L is also used in the food processing, pharmaceutical, and petrochemical industries.

©2024 Vinit Stainless All Rights Reserved.