One of the top producers and suppliers of premium stainless steel products, such as the premium-grade Stainless Steel 904L Tubing, is Vinit Stainless, which has its headquarters in Chennai, India. Vinit Stainless is renowned for its inventiveness, accuracy, and unwavering quality. It provides tubing solutions made to withstand the harshest industrial settings. Because of its exceptional corrosion resistance, especially in harsh environments with acids and chlorides, SS 904L tubing is perfect for use in the chemical processing, oil and gas, and marine sectors. Vinit Stainless is still a reputable brand for durable stainless steel tubing solutions because of its dedication to dependability, performance, and client satisfaction.

Iron makes up the majority of stainless steel 904L tubing, along with significant amounts of nickel (23–28%), chromium (19–23%), molybdenum (4–5%), and copper (1–2%). This alloy has outstanding corrosion resistance, particularly in environments with seawater, sulfuric acid, and chlorides. It provides excellent resistance to pitting, crevice corrosion, and stress corrosion cracking, as well as high tensile strength (490–710 MPa) and good toughness. Its low carbon content lowers the chance of intergranular corrosion and enhances weldability. The tubing is designed to last, require little upkeep, and function reliably in high-pressure and harsh chemical environments.

| Specifications | : | ASTM A/ASME SA213/ A249/ A269 |

| Dimensions | : | ASTM, ASME and API |

| SS 310/ 310S Tubes Size | : | 1/8″NB TO 30″NB IN |

| Schedule | : | SCH20, SCH30, SCH40, XS, STD, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Thickness | : | 0.35mm to 6.35mm OD in thickness ranging from 0.1mm to 1.2mm. |

| Form | : | Round, Rectangular, Square, Hydraulic Etc |

| Type | : | Seamless / Fabricated / ERW / Welded / LSAW Tubes |

| Length | : | Single Random, Double Random & Cut Length. |

| End | : | Plain End, Beveled End, Treaded |

| AISI 904L | Maximum | Minimum |

|---|---|---|

| Ni | 28.00 | 23.00 |

| C | 0.20 | – |

| Mn | 2.00 | – |

| P | 00.045 | – |

| S | 00.035 | – |

| Si | 1.00 | – |

| Cr | 23.0 | 19.0 |

| Mo | 5.00 | 4.00 |

| N | 00.25 | 00.10 |

| CU | 2.00 | 1.00 |

| Element | Grade 904L |

|---|---|

| Density | 8 |

| Melting Range | 1300 -1390 ℃ |

| Tensile Stress | 490 |

| Yield Stress (0.2%Offset) | 220 |

| Elongation | 35% minimum |

| Hardness (Brinell) | – |

Contact us to get a quick quote for your requirement.

We practically assures its customers the top quality concerning their products, Stainless Steel 904L Tubing, with intension testing and certification measures. Each of these products is accompanied by elaborate quality checks ranging from the analysis of the material to tensile strength and corrosion resistance tests. With its international certification, the tubing guarantees excellent performance, performance reliability, and adherence to the demands of a specific industry.

Offering excellent corrosion resistance, Stainless Steel 904L Seamless Tubing is known for its uniformity and strength. It typically comes in sizes ranging from 6mm to 350mm in diameter and lengths of up to 6 meters. Ideal for applications requiring high pressure and corrosive resistance.

Stainless Steel 904L Welded Tubing provides superior resistance to chloride-induced stress corrosion cracking. Available in sizes from 10mm to 150mm in diameter and standard lengths of 6 meters. It is often used in industrial and chemical processing applications where weld strength is critical.

Featuring outstanding corrosion resistance, Stainless Steel 904L Heat Exchanger Tubes are used in demanding environments. Sizes typically range from 6mm to 50mm in diameter, with wall thickness varying from 1mm to 3mm. These tubes are designed for high temperature and pressure conditions.

Stainless Steel 904L Instrumentation Tubing offers excellent resistance to corrosion and is ideal for precise measurement systems. Common sizes include 1/8″ to 1/2″ in diameter and lengths up to 6 meters. It is suitable for high-pressure applications and harsh environments.

With superior resistance to both oxidation and corrosion, Stainless Steel 904L Boiler Tubes are used in high-pressure steam applications. Sizes typically range from 25mm to 100mm in diameter, with lengths of up to 6 meters. They are essential for maintaining efficiency in boiler systems.

Stainless Steel 904L U-tubes provide excellent resistance to corrosive fluids and are commonly used in heat exchangers. Standard sizes range from 10mm to 100mm in diameter with various lengths. They are designed to handle thermal expansion and contraction in dynamic environments.

Stainless Steel 904L Condenser Tubes are used in marine and power generation applications, offering exceptional resistance to seawater and acidic environments. Sizes typically range from 10mm to 50mm in diameter and lengths up to 6 meters, providing durability and efficiency.

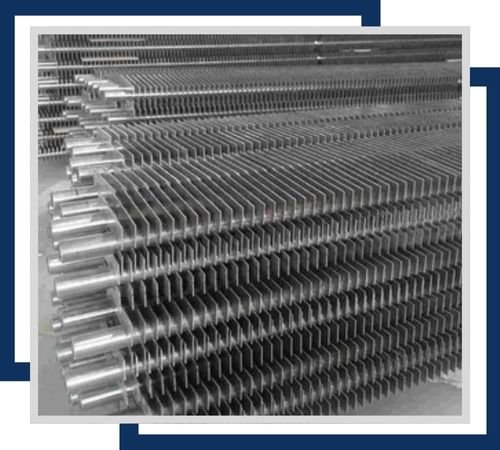

Stainless Steel 904L Fin Tubes are designed for enhanced heat transfer and corrosion resistance in air-cooled heat exchangers. They are available in various diameters, commonly 25mm to 50mm, with fin lengths customizable to specific requirements, ensuring effective cooling in challenging environments.

Industries that demand high mechanical strength and remarkable resistance to corrosive agents frequently use stainless steel 904L tubing. It is perfect for dealing with strong acids like sulfuric and phosphoric acid in the chemical and pharmaceutical industries. It is employed for offshore drilling and refining in the oil and gas sector. Additionally, the tubing functions dependably in seawater cooling systems, desalination plants, and marine environments—all of which depend on chloride resistance. Heat exchangers, pressure vessels, and aerospace components are further applications where corrosion resistance, weldability, and structural stability are critical for long-term operational effectiveness.

©2024 Vinit Stainless All Rights Reserved.