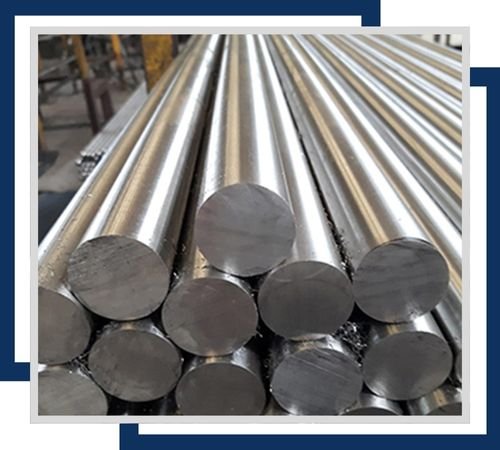

Based in Chennai, India, Vinit Stainless is a well-known manufacturer and supplier of high-quality stainless steel bars to a variety of industries. We provide long-lasting and corrosion-resistant stainless steel solutions to the manufacturing, automotive, aerospace, and construction industries with a strong emphasis on quality, accuracy, and client satisfaction. Our products are designed to satisfy a wide range of industrial needs and are tailored to the needs of our customers. Vinit Stainless is the recommended option for stainless steel bar supply for both domestic and international projects because we are a reputable brand in the Indian market that guarantees prompt delivery, affordable prices, and dependable assistance.

Vinit Stainless’s stainless steel bars are made up of 10–20% chromium and 8–12% nickel. To improve mechanical performance and corrosion resistance, trace amounts of molybdenum, manganese, and carbon may also be added. These bars exhibit high tensile strength, excellent ductility, and superior resistance to oxidation, staining, and environmental wear. They are appropriate for fabrication and finishing procedures due to their formability and machinability. These bars are made to last a long time and maintain their structural integrity. They meet both national and international standards, guaranteeing top performance in critical and general-purpose applications.

| Stainless Steel Bar Length | 2 to 6 meters or 8 to 20 feet |

|---|---|

| SS Rod Chamfering | Available in 30, 45 & 60 degree thru fully automatic both-end chamfering machine |

| Ultrasonic Test of ASTM A276 Threaded Rod | As per ASTM A-388, EN 10308 (class 1 to 4), API 6A/ISO it is 100% tested thru Digital Ultrasonic Flaw Detector, 10423:2003-PSL 3, MIL STD 2154, SEP 1920:1984 |

| SS Round Bar Size Tolerances | h11 |

| Tolerance of Cold Rolled SS Round Bar Length | Stock in special cut to length bar in tolerance – 0/+10mm (-0 +0.5 inch) |

| Surface Finish of Cold Rolled SS Bar | Cold drawn or Belt polished condition |

| Bar Heat Treatment | Annealed and Solution Annealed |

| Element | Stainless Steel Bars |

| Ni | 8.0 – 10.5 |

| C | 0.08 |

| Mn | 2.0 max |

| P | 0.045 max |

| S | 0.030 max |

| Si | 0.75 max |

| Cr | 15.0 – 18.0 |

| Mo | – |

| N | 0.10 |

| Element | SS Bars |

| Tensile Strength (MPa) min | 515 |

| Yield Strength 0.2% Proof (MPa) min | 205 |

| Elongation (% in 50mm) min | 40 |

| Rockwell B (HR B) max Hardness | 92 |

| Brinell (HB) max Hardness | 201 |

Contact us to get a quick quote for your requirement.

We ensure the full transparency of our Stainless Steel Bars with high-quality assurance. All orders have essential documents in the form of a commercial invoice, packing list, fumigation certificate, heat treatment chart, and a NABL-approved lab test report. We offer Material Test Certificate per EN 10204/3.1b, PMI Test Certificate, 100% radiography test report, and Third-Party Inspection Certificate. Our total documentation is arranged to ensure maximum client satisfaction.

Yes, Stainless Steel Bars are highly corrosion-resistant due to the presence of chromium, which forms a protective oxide layer. This makes them ideal for use in harsh environments.

The pressure rating of stainless steel bars depends on factors such as grade, size, and application. Typically, they are designed to withstand high pressures, ranging from 150 to 1,000 PSI, depending on specifications.

Yes, stainless steel bars can be ordered in custom sizes and polishes to meet specific requirements. Many suppliers offer customization options for dimensions, finishes, and surface treatments. For more details mail us on sales@vinitstainless.co.in

Because of their strength, resilience to corrosion, and durability, stainless steel bars are highly prized for a variety of applications. They are utilized for frameworks, railings, and structural reinforcements in construction. They are used in frames, fasteners, and engine parts in the automotive and aerospace industries. These bars are used in the manufacturing sector for precision components, tools, and machinery parts. They are also appropriate for architectural and ornamental uses due to their aesthetic appeal. They are a preferred material in the food processing, chemical, and marine industries where strength, dependability, and cleanliness are crucial because they can withstand harsh environments.

©2024 Vinit Stainless All Rights Reserved.