Vinit Stainless is a well-known producer and supplier of high-quality stainless steel SMO 254 bars, situated in Chennai, India, an industrial center. Vinit Stainless provides top-notch stainless steel solutions to domestic and international industries with a focus on quality and accuracy. The business is well-known for its dedication to quality, professionalism, and client satisfaction. It sells cutting-edge SMO 254 bar products that offer exceptional strength and resistance to corrosion in harsh conditions. Vinit Stainless guarantees dependability, durability, and performance with each bar made to the highest international standards, whether for high-salinity, chemical, or marine applications.

Austenitic stainless steel bars with a high alloy content of 20% chromium, 18% nickel, 6% molybdenum, and a trace amount of nitrogen are known as stainless steel SMO 254 bars. Particularly in chloride-rich environments, this special composition provides outstanding resistance to pitting, crevice corrosion, and stress corrosion cracking. Excellent mechanical qualities, such as high tensile strength, good weldability, and superior ductility, are provided by SMO 254 bars. With their stable microstructure and increased strength at high temperatures, these bars are perfect for use in harsh conditions where resistance to pressure, mechanical stress, and corrosive elements is necessary.

| Standards | EN, DIN, JIS, ASTM, BS, ASME, AISI |

|---|---|

| Size | 1/2″ to 100″ |

| Length | 100 mm to 6000 mm |

| Specifications | ASTM A276, A279, A479 |

| Form | Round, Square, Hex (A/F), Rectangle, Wire (Coil Form), Wire-mesh, Billet, Ingot, Forging Etc. |

| Finish | Bright, Polish, Black |

| SMO 254 | Ni | C | Mo | Mn | Si | Fe | Cu | S | P | Cr |

| 17.5 – 18.5 | 0.02 max | 6 – 6.5 | 1 max | 0.8 max | – | 0.5 – 1 | 0.01 max | 0.03 max | 19.5 – 20.5 |

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 8.0 g/cm3 | 1320-1390 ℃ | 300 | 650 | 35 % |

Contact us to get a quick quote for your requirement.

We thoroughly tests and certifies its Stainless Steel SMO 254 Bars with the highest quality standards. Every product undergoes rigorous checks including chemical composition analysis, mechanical testing, and corrosion tests. Under relevant industry standards, these certified products could assure reliability and performance and ensure global specifications are met.

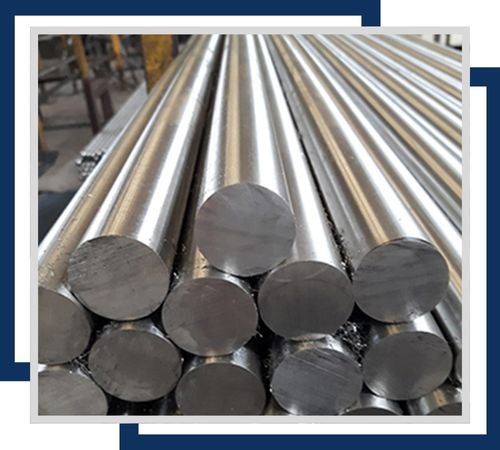

Stainless Steel SMO 254 Round Bars offer exceptional resistance to corrosion and high strength, ideal for marine and chemical processing applications. Their high molybdenum content ensures durability and performance in aggressive environments.

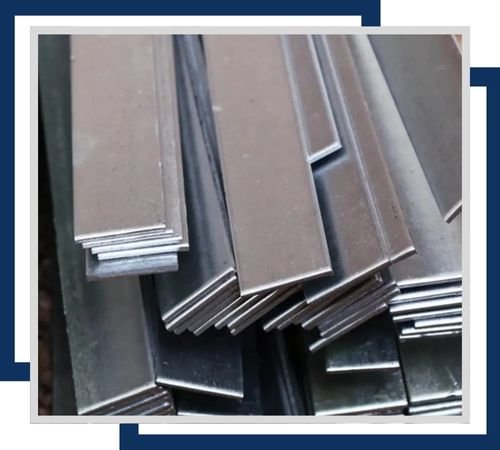

Stainless Steel SMO 254 Flat Bars provide superior resistance to corrosion and pitting, making them suitable for use in harsh marine and chemical environments. They are commonly used in structural components and equipment exposed to severe conditions.

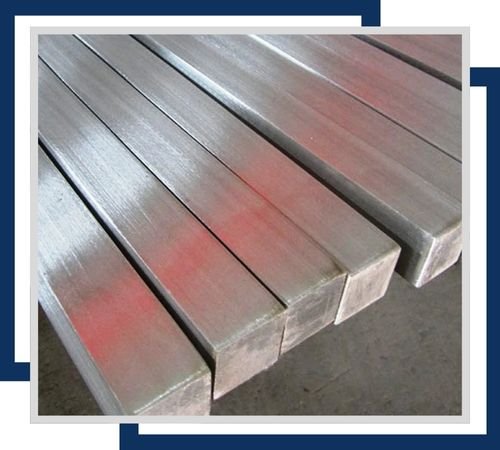

Stainless Steel SMO 254 Square Bars are designed for applications requiring high corrosion resistance and strength. They are ideal for use in chemical processing, marine environments, and offshore platforms, offering excellent durability and performance.

Stainless Steel SMO 254 Rectangular Bars are used in environments where resistance to corrosion and high strength are crucial. They are employed in structural supports, chemical processing equipment, and marine applications, ensuring long-lasting performance.

Stainless Steel SMO 254 Hexagonal Bars offer enhanced resistance to corrosion and oxidation, making them ideal for use in high-salinity and chemical environments. They are commonly used in marine applications and industrial components requiring superior durability.

Stainless Steel SMO 254 T-Bars provide exceptional strength and resistance to corrosive environments. They are suitable for structural applications, chemical processing equipment, and marine environments, ensuring reliability and longevity under extreme conditions.

Industries that need remarkable corrosion resistance and mechanical strength in harsh conditions frequently use stainless steel SMO 254 bars. They are utilized in pressure vessels, heat exchangers, and reactors in chemical processing. They are appropriate for offshore and marine applications due to their high resistance to corrosion from saltwater. They are used in the piping and pumps of desalination plants. SMO 254 is used in the food processing and pharmaceutical industries because of its non-reactive and hygienic qualities. It is also useful in the production of medical equipment, power plants, and aircraft due to its strength and durability at high temperatures.

©2024 Vinit Stainless All Rights Reserved.