Home > Dairy Fittings > TC Liner

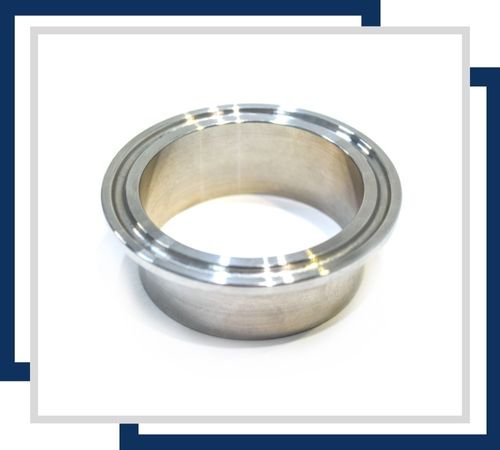

Vinit Stainless, Chennai, India’s reliable manufacturer and supplier, offers superior TC Liners, key components in establishing sanitary and secure connections for hygienic piping systems. The liners are accurately machined to provide a snug fit with TC clamps and ferrules, ensuring a leak-proof seal that is imperative for sensitive applications. We dedicate ourselves to delivering dependable components that satisfy demanding sanitary requirements, sustaining the integrity and effectiveness of your fluid handling operations.

TC Liners are primarily manufactured from high-grade stainless steel, most commonly 304L or 316L. The low carbon content in these grades prevents carbide precipitation during welding, enhancing corrosion resistance. Their composition ensures excellent resistance to a wide range of chemicals and cleaning agents. Mechanically, TC Liners offer high tensile strength and rigidity, ensuring robust and stable connections. Their smooth, polished internal surface further contributes to hygienic fluid flow and prevents bacterial buildup.

Thickness : 1.0 to 5 milimeter, 12, 14, 16, 18, 20 SWG

Sizes : 1/4 to 6 inch

Outside Diameter : 1/4 NB. – 8 NB inch., 1/4 – 8 inch Outside dia

Grade : SS 201, 202, 304, 310S, 321, 304L, 316, 316L, 904L

Standards : TRICLOVER / DIN / BSP / SMS / IDF / NPT

Contact us to get a quick quote for your requirement.

We ensures that all TC Liner products are stringently tested for quality, strength, and durability. All liners undergo comprehensive tests-checking material composition, corrosion resistance, and pressure tests; the products are certified to meet international industry standards. These liners provide outstanding performance and reliability for demanding applications.

SS 304 TC Liner is a durable, corrosion-resistant liner made from stainless steel 304. It is commonly used in various sanitary and food processing applications due to its high resistance to oxidation and corrosion. Available in various sizes, it provides reliable performance in high and low temperatures.

Stainless Steel 304L Tri Clamp Liner offers excellent corrosion resistance with low carbon content, enhancing its suitability for welding applications. It is designed for tri-clamp fittings in sanitary processes, ensuring a secure and leak-proof connection. This liner is available in multiple sizes to meet specific operational requirements.

SS 316 Dairy Triclover Liner is crafted from stainless steel 316, providing superior resistance to corrosion and chemical reactions, making it ideal for dairy and food processing industries. It is designed to fit tri-clover fittings and is available in various sizes to accommodate different system configurations.

Stainless Steel 316L Tri Clamp Sanitary Liner is made from 316L stainless steel and is known for its excellent resistance to corrosion and pitting. It is used in sanitary and pharmaceutical applications where high purity is essential. This liner comes in various sizes to fit standard tri-clamp fittings.

Stainless Steel Dairy Triclover Liner is specifically designed for dairy applications, offering exceptional resistance to corrosion and scaling. Made from high-grade stainless steel, it ensures durability and hygiene. Available in various sizes, it is suitable for various dairy processing setups.

Stainless Steel Dairy TC Liner provides robust corrosion resistance and is ideal for dairy processing systems. Its stainless steel construction ensures longevity and reliability in maintaining product integrity. The liner is available in different sizes to match the requirements of various dairy processing systems.

TC Liners are critical parts of hygienic piping systems in many industries. They are used widely in the food and drink industry for pipe, valve, and equipment connection in breweries, dairies, and soft drink manufacturing plants. In pharmaceutical and biotechnology industries, they provide sterile and contamination-free fluid transfer lines. TC Liners are also critical in cosmetic and fine chemical applications where product cleanliness and cleanability are essential, offering a more secure and clean interface for numerous equipment processing applications.

©2024 Vinit Stainless All Rights Reserved.